http://www.cnc4pc.com/Store/osc/product ... cts_id=323

trying to calibrate and its not going so well.

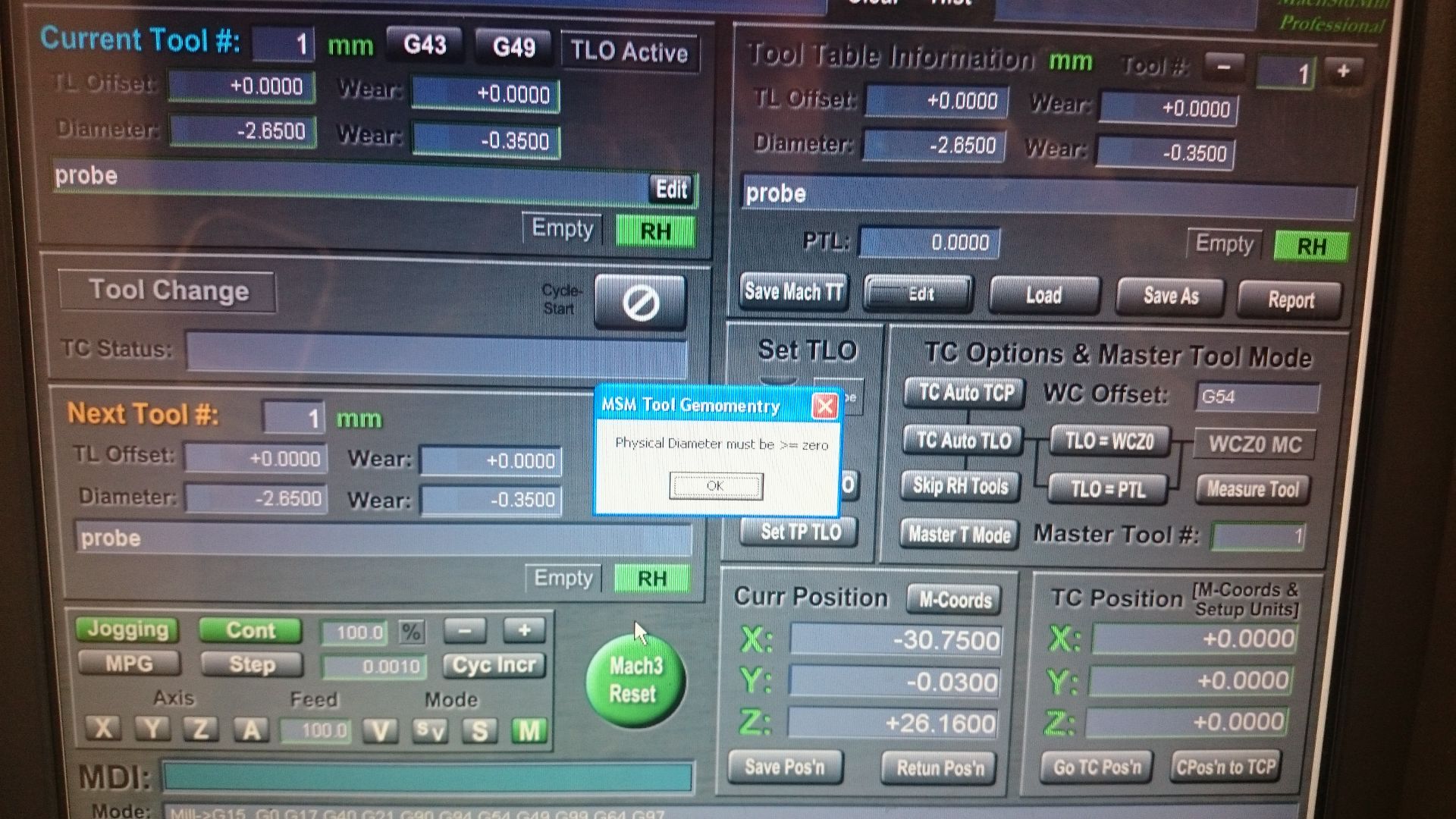

the tip of the probe is 2.65mm dia

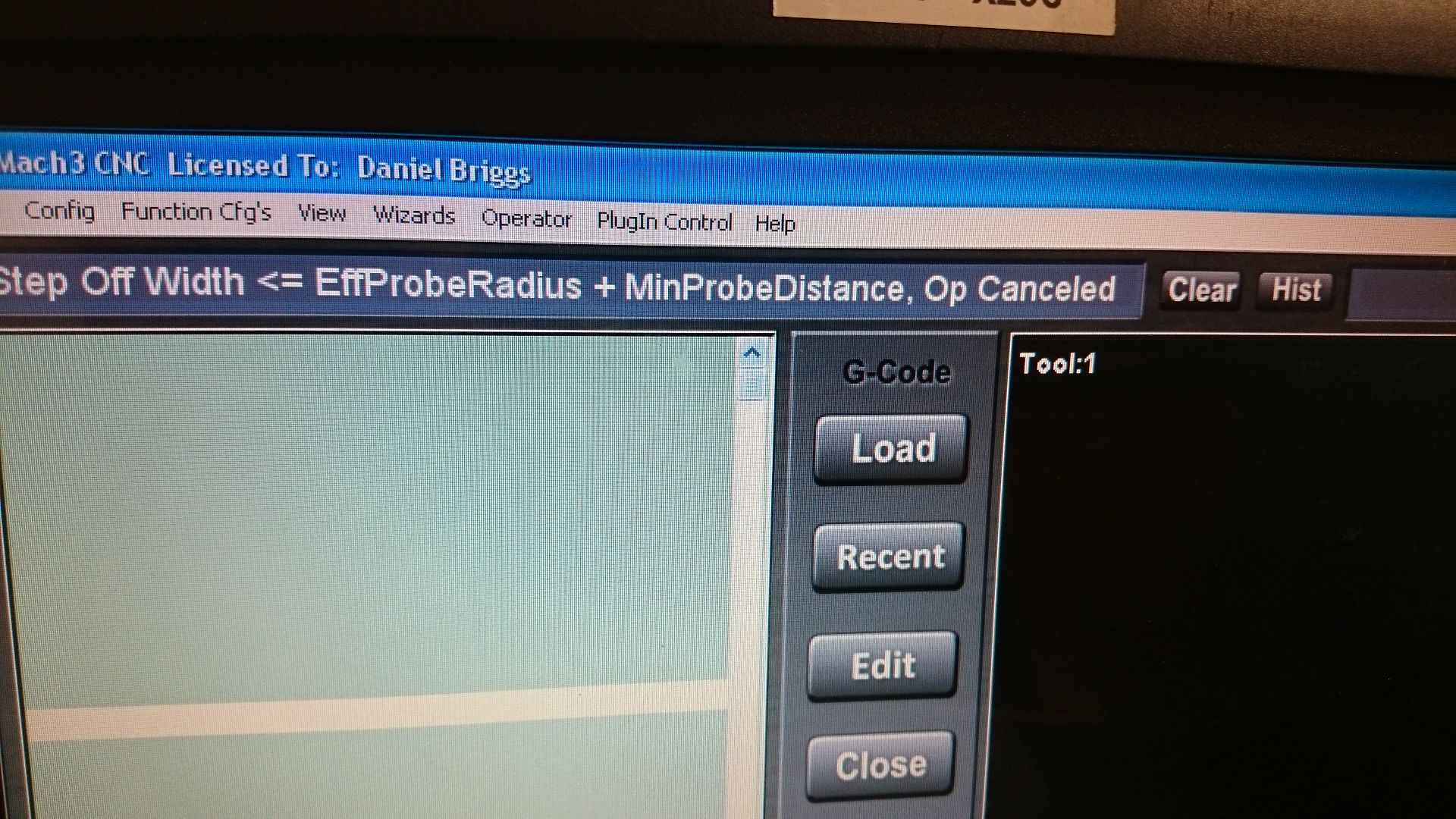

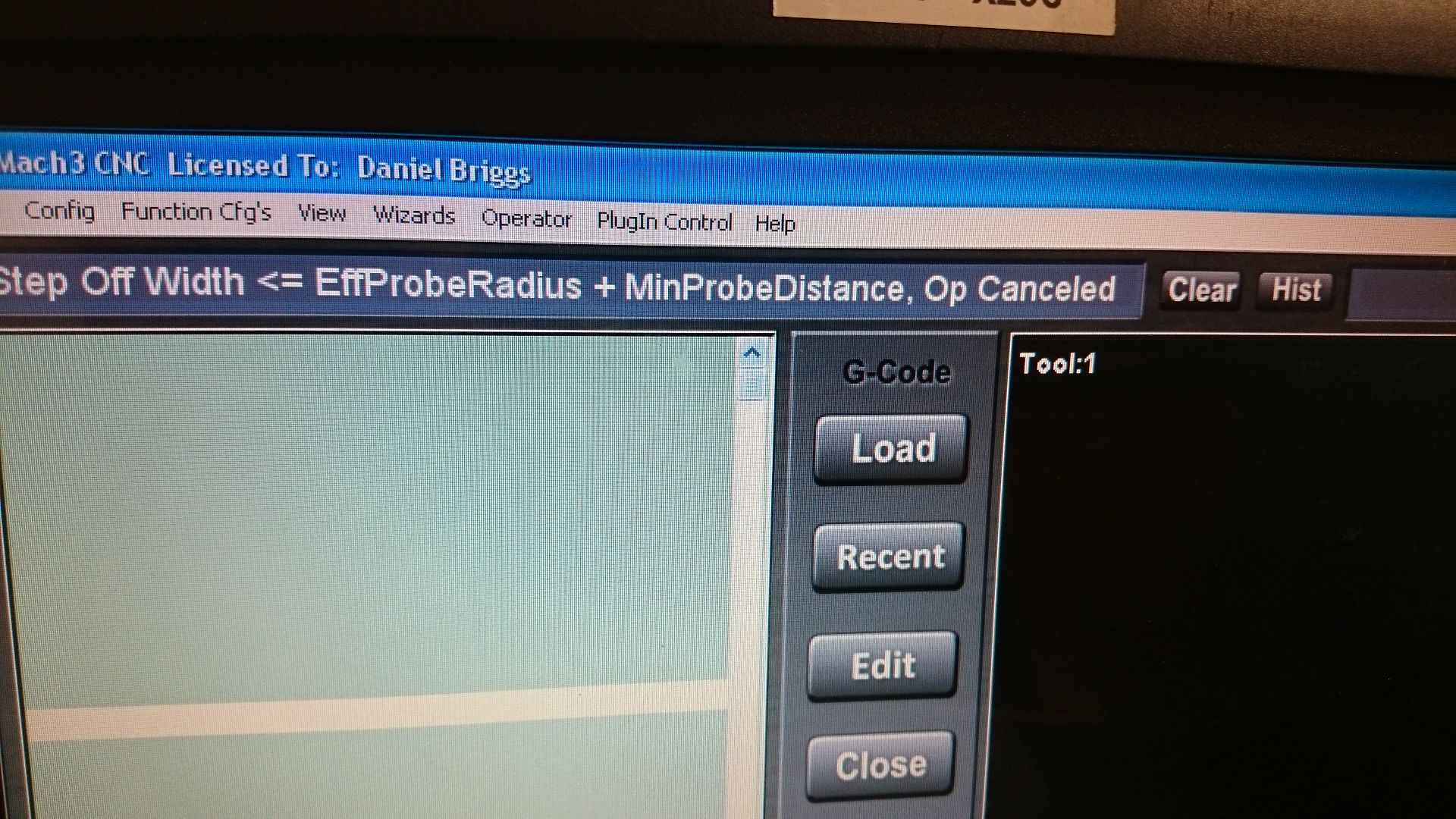

the hole in using is 8.5mm so plenty of room for the probe tip inside, but I keep getting this error

On the probing page with all the probing parameters, what value do you have the step of width set to?andy_con wrote:just installed one of thee today

http://www.cnc4pc.com/Store/osc/product ... cts_id=323

trying to calibrate and its not going so well.

the tip of the probe is 2.65mm dia

the hole in using is 8.5mm so plenty of room for the probe tip inside, but I keep getting this error

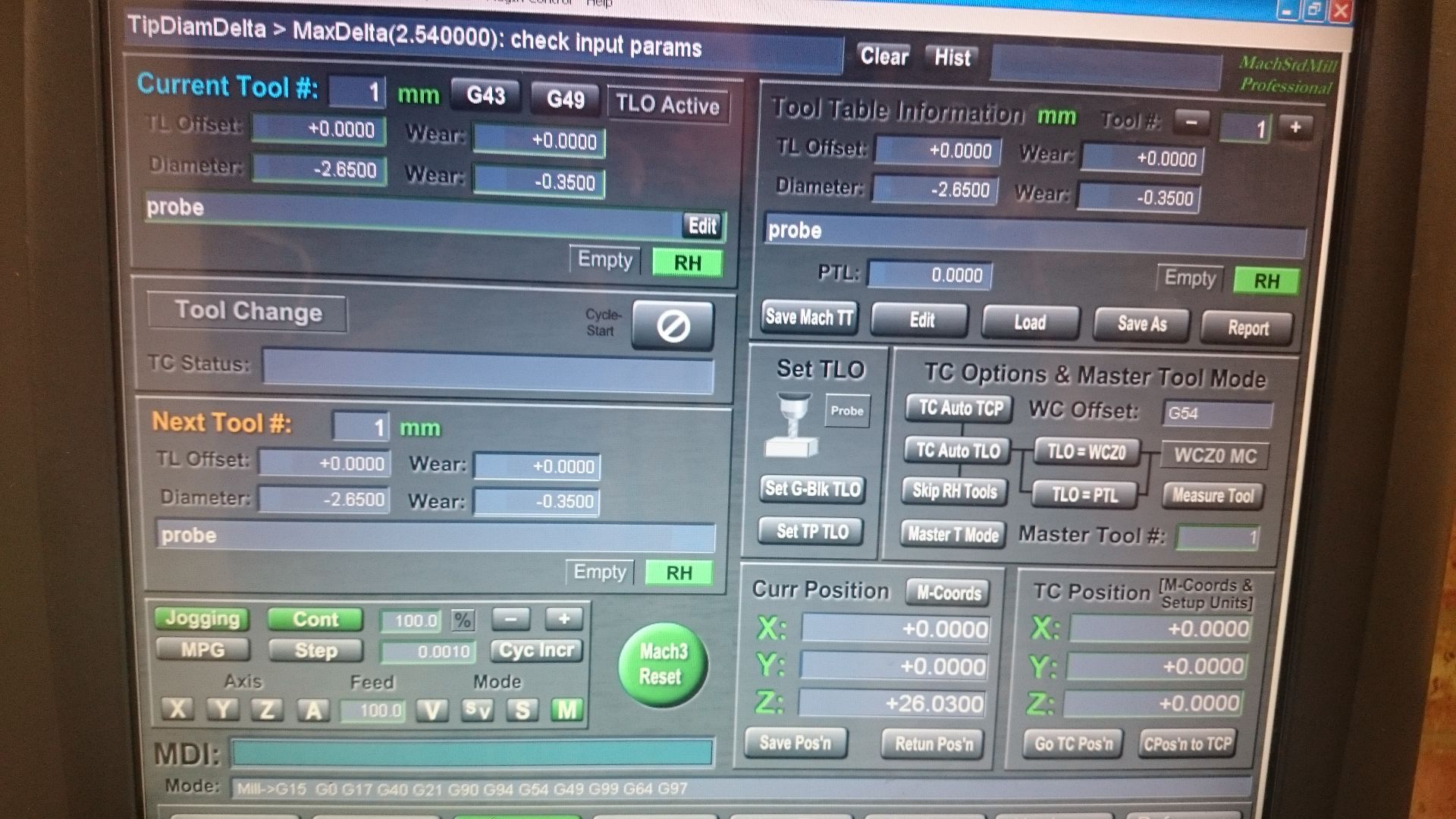

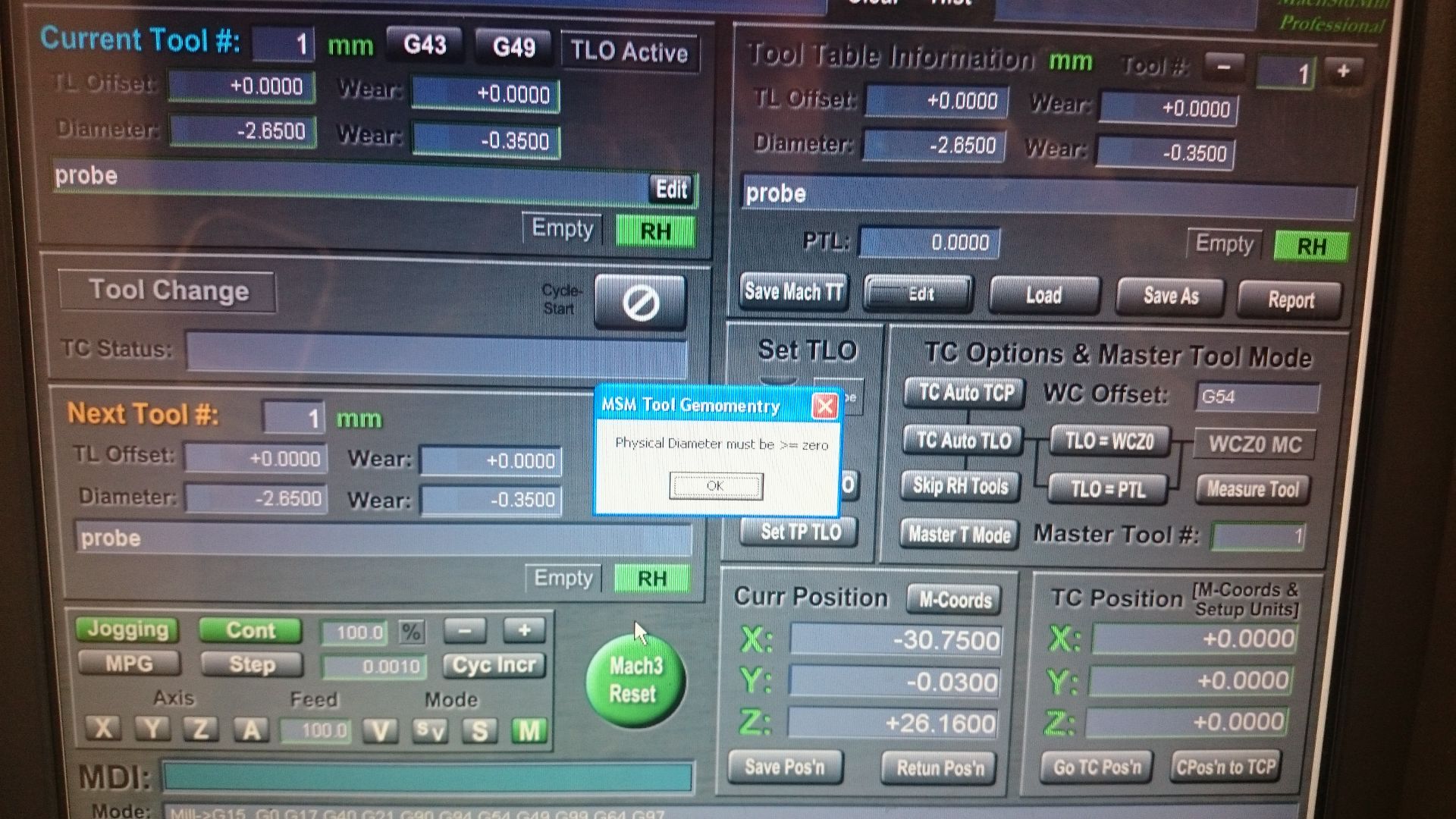

OK, let's back up and do a sanity check here... A tool diameter can not physically be a negative number... It just is not possible. A tool has to have a positive diameter ( at least in my part of the worldandy_con wrote:um not really getting anywhere, so put the dia of the probe tip in the dia field but it only works if its a - number.

the wear seems to be the figure given by the calibration function

Yes the forum is active. Please understand that Calypso Ventures in located on the West coast of the US and we are in the pacific time zone. Your posts are time stamped Friday afternoon.... our apologies but we did not see them on Friday and occasionally we do something other than business/work on the weekends. Even so, this post is being responded to on a Sunday evening local time.andy_con wrote: but im still getting errors, is this forum still active?

I sounds as if maybe you installed the probe, and dove right into the probe calibration stuff.. maybe without first going thru the simpler probe operations? If so, you would not be the first to do so.andy_con wrote: heres a few screen shots to show how its setup

cant get past this error at the moment

step of width is set to 0.5mm, so ill give this a tweak tonight and see how it goes.DaveCVI wrote:Hi,On the probing page with all the probing parameters, what value do you have the step of width set to?andy_con wrote:just installed one of thee today

http://www.cnc4pc.com/Store/osc/product ... cts_id=323

trying to calibrate and its not going so well.

the tip of the probe is 2.65mm dia

the hole in using is 8.5mm so plenty of room for the probe tip inside, but I keep getting this error

I suspect you have it set to 0 ro a very small value.

When you click to a "sown and over" operation, the system probes for Z then tries to move i X or Y (depends on the operation) to get off past the edge. Before tying to do so, it sanity checks the current settings - the message is saying that the step off width is too small to get off the edge and over the "hole" for the operation. We know we just touched the tip center on the horiz Z surface - The step of width has to be, at an absolute minimum, greater than the probe tip radius plus a tad. If that is not true, there is no point trying to go over and then down as we know the down will fail. So I suspect either the step off width is really small or the tool table diameter entry is really large.

Dave

im used to big forums where you post something and someone response pretty quickyl, sorryDaveCVI wrote:HiOK, let's back up and do a sanity check here... A tool diameter can not physically be a negative number... It just is not possible. A tool has to have a positive diameter ( at least in my part of the worldandy_con wrote:um not really getting anywhere, so put the dia of the probe tip in the dia field but it only works if its a - number.

the wear seems to be the figure given by the calibration function)

So MSM sees a negative diameter value and puts up a message that a negative diameter makes no sense.

It can probably be argued that it's a bug that it ever allowed a negative tool diameter to be entered in the first place. {/quote]

i did think it was stange but ill have another play tonight and see how things go

Yes the forum is active. Please understand that Calypso Ventures in located on the West coast of the US and we are in the pacific time zone. Your posts are time stamped Friday afternoon.... our apologies but we did not see them on Friday and occasionally we do something other than business/work on the weekends. Even so, this post is being responded to on a Sunday evening local time.andy_con wrote: but im still getting errors, is this forum still active?

I sounds as if maybe you installed the probe, and dove right into the probe calibration stuff.. maybe without first going thru the simpler probe operations? If so, you would not be the first to do so.andy_con wrote: heres a few screen shots to show how its setup

cant get past this error at the moment

Ah.. the videos were intended as a supplement to the user manual, but not as an alternative to it.andy_con wrote:

i didnt completely dive in, i watched the videos i could find on youtube about the probing operation. but i couldnt find one on setting up each field on the probing page. so thats where im struggling.

No need to download the manual- it's installed with MSM. Just go to the reference page and click the user manual button and it'll open up in whatever pdf reader you have configured. If you've not yet told MSM what to use for a pdf reader, it'll ask you to point it to the pdf reader program and then open the manual file (it'll then remember the pdf reader for you).andy_con wrote: but ill download the manual and have a look later cheers.

Go to the tooling page, use the upper right panel to edit the diameter for the probe tool and change it from a negative diameter (which is physically impossible) to a positive diameter. Also set the sear value to 0 while you are there. I think you said the probe tip diameter was 2.63 mm, so the tool table should have the diameter = 2.63mm (NOT -2.63 mm!) and wear diameter = 0.andy_con wrote:ok thanks will do that

am really really struggling with this error, I cannot get past it

any tips?

no matter what figures I put in I get this error